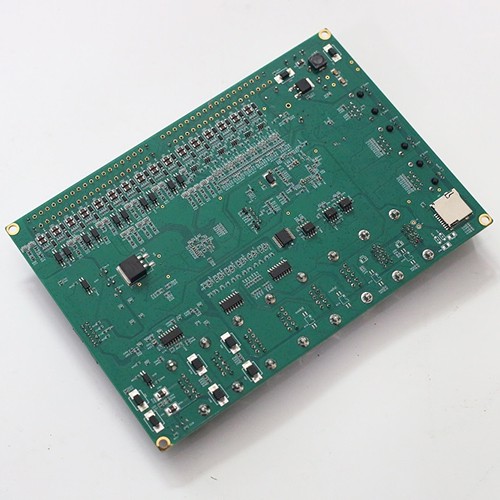

Intelligent lithium battery production equipment control system

The design of the control system for intelligent lithium battery production equipment needs to consider the mixed production mode of small batches of multiple specifications to achieve the compatibility of the production line and the beat control of the entire line

Intelligent lithium battery production equipment control system is the key technology to ensure accurate control of each link in the lithium battery production process.

Here are some key points:

1. High-precision control: The intelligent control system needs to be able to accurately control the current and voltage during battery charging and discharging, as well as the pressure and temperature during the production process.

2. Modular design: In order to adapt to different battery production processes, the control system needs to support modular design to facilitate flexible configuration of production capacity.

3. Data collection and analysis: The intelligent control system collects various data on the production line, such as current, voltage, temperature, pressure, etc., and conducts real-time monitoring and data analysis to optimize the production process.

4. Edge computing: The edge computing technology can be used to process data at the source of data generation, reduce data transmission time, and improve response speed.

5. Internet of Things (IoT): Through the Internet of Things technology, the equipment on the production line is connected to achieve interconnection between equipment and improve production efficiency.

Predictive maintenance: The intelligent control system can monitor the status of equipment in real time and predict potential failures, thereby reducing unplanned downtime and improving production stability.

6. Flexible production: The intelligent control system supports flexible production and can automatically adjust the production line according to order requirements and production capacity to achieve multi-variety and small-batch production.

7. Quality control: By integrating SPC (statistical process control) and SQC (statistical quality control) tools, the intelligent control system can monitor the production process in real time to ensure product quality.

8. Energy management: The intelligent control system can monitor energy consumption, optimize energy use, reduce production costs, and achieve green production.

9. MES system: As the core of the intelligent control system, the manufacturing execution system (MES) can realize the automation of production planning, scheduling, execution, tracking and control.

With the development of technology, the control system of intelligent lithium battery production equipment will be more intelligent and automated, improve production efficiency and product quality, reduce costs, and achieve green manufacturing.

Intelligent lithium battery production equipment control system is the key technology to ensure accurate control of each link in the lithium battery production process.

Here are some key points:

1. High-precision control: The intelligent control system needs to be able to accurately control the current and voltage during battery charging and discharging, as well as the pressure and temperature during the production process.

2. Modular design: In order to adapt to different battery production processes, the control system needs to support modular design to facilitate flexible configuration of production capacity.

3. Data collection and analysis: The intelligent control system collects various data on the production line, such as current, voltage, temperature, pressure, etc., and conducts real-time monitoring and data analysis to optimize the production process.

4. Edge computing: The edge computing technology can be used to process data at the source of data generation, reduce data transmission time, and improve response speed.

5. Internet of Things (IoT): Through the Internet of Things technology, the equipment on the production line is connected to achieve interconnection between equipment and improve production efficiency.

Predictive maintenance: The intelligent control system can monitor the status of equipment in real time and predict potential failures, thereby reducing unplanned downtime and improving production stability.

6. Flexible production: The intelligent control system supports flexible production and can automatically adjust the production line according to order requirements and production capacity to achieve multi-variety and small-batch production.

7. Quality control: By integrating SPC (statistical process control) and SQC (statistical quality control) tools, the intelligent control system can monitor the production process in real time to ensure product quality.

8. Energy management: The intelligent control system can monitor energy consumption, optimize energy use, reduce production costs, and achieve green production.

9. MES system: As the core of the intelligent control system, the manufacturing execution system (MES) can realize the automation of production planning, scheduling, execution, tracking and control.

With the development of technology, the control system of intelligent lithium battery production equipment will be more intelligent and automated, improve production efficiency and product quality, reduce costs, and achieve green manufacturing.