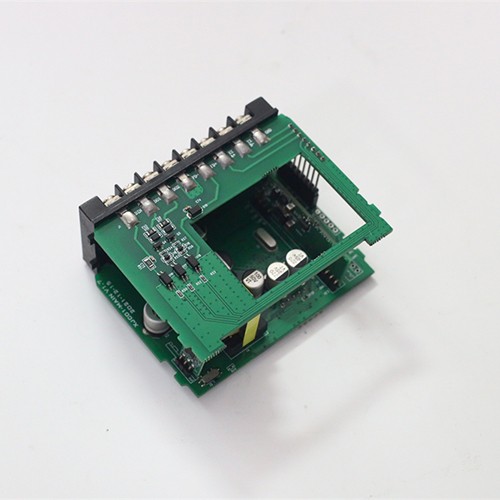

Lithium battery test monitoring system

The lithium battery test monitoring system is a key device for monitoring and managing lithium battery performance, which is essential to ensure battery safety, improve battery performance and extend battery life.

Lithium battery test monitoring system is a key equipment used to monitor and manage lithium battery performance, which is essential to ensure battery safety, improve battery performance and extend battery life. The following are the main application areas and technical specifications of the lithium battery testing and monitoring system:

Application areas:

1. Battery manufacturing: In the battery production line, it is used for battery formation, capacity separation, detection and quality control.

2. Electric Vehicles (EV): Used to monitor and manage the performance and status of electric vehicle battery packs.

3. Energy Storage Systems: In solar or wind energy storage systems, used to monitor the status of battery storage units.

4.Aerospace: For battery system monitoring in aircraft and drones.

5.Research and Development: In a laboratory environment, for research and development of battery technology.

6. Industrial Automation: In automated production lines, used to monitor and optimize battery performance.

Technical Specifications:

1. High-precision monitoring: Capable of accurately measuring the battery’s voltage, current, temperature and internal resistance.

2.Data logging: Long-term data logging function to track battery performance and status.

3.Communication interface: Supports communication with host computer or other monitoring systems, such as CAN bus, Ethernet, RS232/RS485, etc.

4.Automated testing: Able to automatically execute complex test procedures, including cycle life test, safety performance test, etc.

5.Safety protection: With overcharge, over discharge, overheating, short circuit and other protection functions.

6.Energy Feedback: Supports the discharge energy to feed back to the grid to improve energy efficiency.

7.User Interface: Provides an intuitive user interface for easy operation and monitoring.

8.Software Support: Equipped with professional testing and analysis software for data processing and report generation.

The design and implementation of the lithium battery test and monitoring system need to consider the battery type, application requirements, test standards and safety requirements to ensure the reliability and effectiveness of the system.

Lithium battery test monitoring system is a key equipment used to monitor and manage lithium battery performance, which is essential to ensure battery safety, improve battery performance and extend battery life. The following are the main application areas and technical specifications of the lithium battery testing and monitoring system:

Application areas:

1. Battery manufacturing: In the battery production line, it is used for battery formation, capacity separation, detection and quality control.

2. Electric Vehicles (EV): Used to monitor and manage the performance and status of electric vehicle battery packs.

3. Energy Storage Systems: In solar or wind energy storage systems, used to monitor the status of battery storage units.

4.Aerospace: For battery system monitoring in aircraft and drones.

5.Research and Development: In a laboratory environment, for research and development of battery technology.

6. Industrial Automation: In automated production lines, used to monitor and optimize battery performance.

Technical Specifications:

1. High-precision monitoring: Capable of accurately measuring the battery’s voltage, current, temperature and internal resistance.

2.Data logging: Long-term data logging function to track battery performance and status.

3.Communication interface: Supports communication with host computer or other monitoring systems, such as CAN bus, Ethernet, RS232/RS485, etc.

4.Automated testing: Able to automatically execute complex test procedures, including cycle life test, safety performance test, etc.

5.Safety protection: With overcharge, over discharge, overheating, short circuit and other protection functions.

6.Energy Feedback: Supports the discharge energy to feed back to the grid to improve energy efficiency.

7.User Interface: Provides an intuitive user interface for easy operation and monitoring.

8.Software Support: Equipped with professional testing and analysis software for data processing and report generation.

The design and implementation of the lithium battery test and monitoring system need to consider the battery type, application requirements, test standards and safety requirements to ensure the reliability and effectiveness of the system.

- Previous:Energy storage + BMS control board

- Next:Inverter motherboard