Why do we need to conduct PCBA testing?

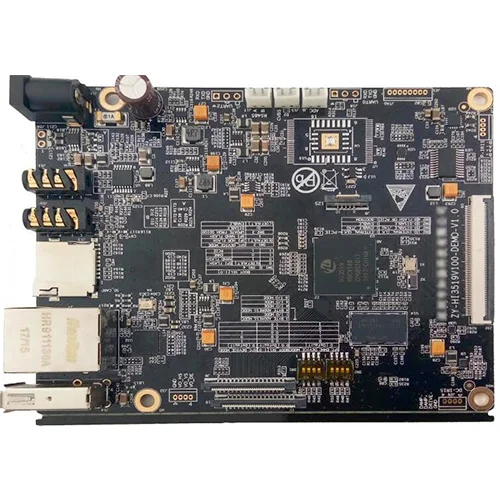

PCBA finished products must be tested and adjusted to meet the specified technical requirements. PCBA processing is just to assemble, connect and weld hundreds of electronic components according to the requirements of the design drawings. The characteristic parameters of each component inevitably have slight differences. The combined result will cause large deviations in the various performances in the PCBA product circuit. In addition, due to the influence of various distributed parameters generated in PCBA processing, it is impossible for the PCBA circuit to work normally immediately after assembly, so that various technical indicators meet the design requirements. Therefore, PCBA testing must be carried out.

Purpose of PCBA testing

PCBA testing is to adjust and test PCBA according to the test process to achieve the functions and technical indicators specified in the technical documents. PCBA is not only an important process to ensure and realize the functions and quality of electronic products, but also an important link to discover the design, process defects and deficiencies of electronic products. To a certain extent, PCBA testing provides a reliable basis for technical performance parameters for the finalization of electronic products.

Main contents of PCBA testing

PCBA testing mainly involves the adjustment of circuit parameters, that is, adjusting the adjustable components of PCBA and the tuning system and mechanical transmission parts related to electrical indicators to achieve the predetermined performance requirements. Based on the basic theory of adjustment, the various technical indicators of the whole machine are systematically tested to ensure that the various technical indicators of the PCBA finished product meet the specified requirements. Specifically, the contents of PCBA testing include the following points.

1. Clarify the purpose and requirements of PCBA testing.

2. Correctly and reasonably select and use test instruments.

3. Adjust and test PCBA according to the test process.

4. Use the basic theoretical knowledge of circuits and components to analyze and eliminate faults that occur during debugging.

5. Analyze and process PCBA test data.

6. Write a test summary based on the test results and put forward suggestions for PCBA processing improvement.

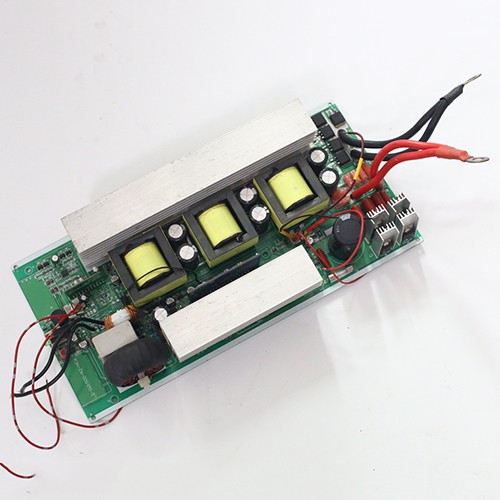

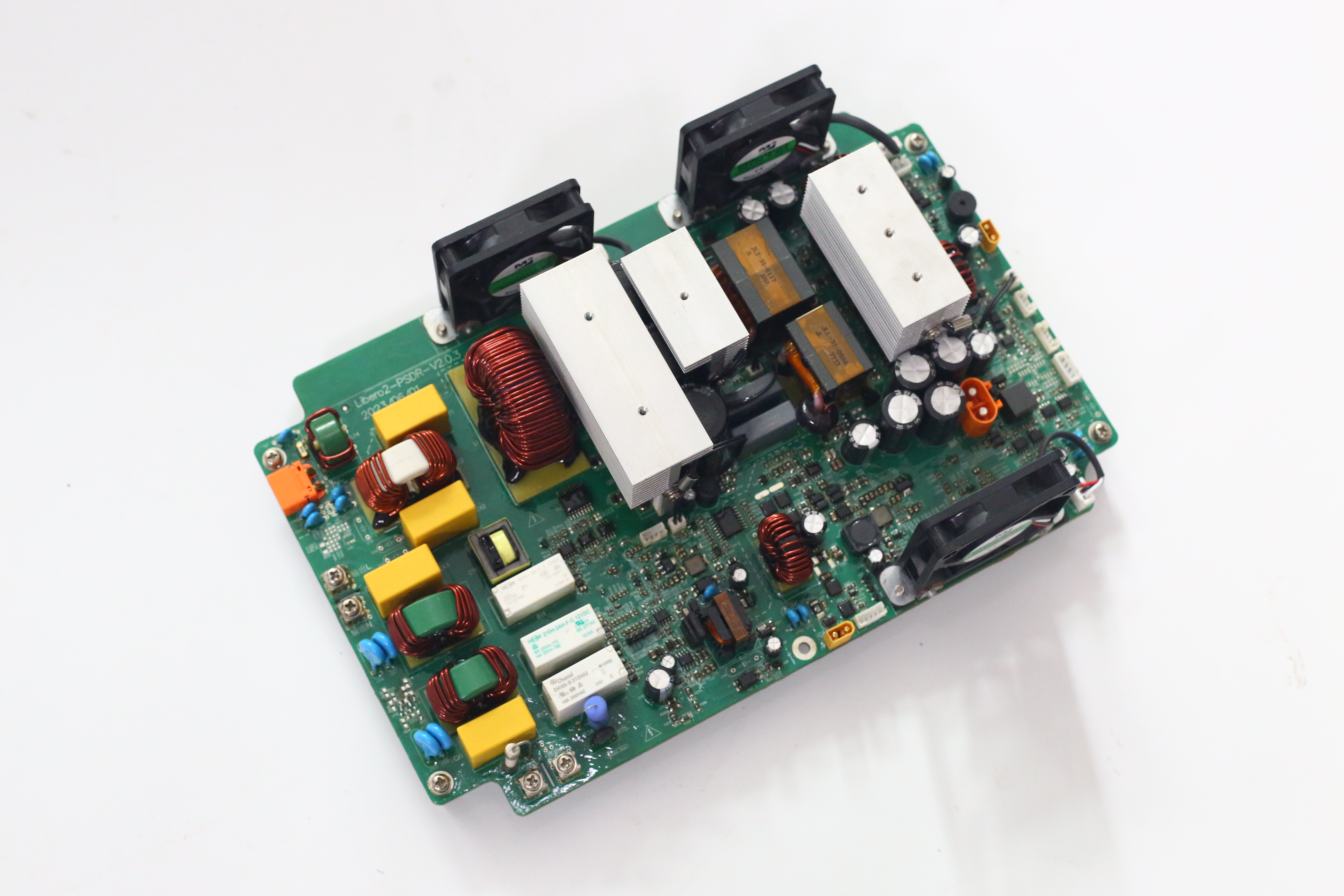

Simple small PCBA processing, such as set-top box modules, semiconductor radio modules, etc., has simple testing work. Generally, the whole machine can be tested directly after assembly is completed. However, complex whole machines, such as automotive electronic control units, have heavy testing work. Usually, the unit board or extension is tested first. After meeting the requirements, the final assembly is carried out, and finally the whole machine is tested.

PCBA testing is generally carried out in the assembly workshop and strictly follows the testing process. For more complex large equipment, partial testing or rough adjustment can be carried out in the production plant according to the design requirements, and then the final installation and comprehensive testing work are carried out at the installation site or experimental base according to the requirements of the technical documents.