1. Customer demand communication (most critical)

Product use (such as ELD equipment, smart home, medical equipment)

Functional requirements (which sensors, communication methods, input and output, interfaces, etc.)

Volume/size/appearance restrictions

Environmental requirements such as working voltage, current, temperature, etc.

Whether to carry out software development (MCU program, driver, APP, etc.)

2. Solution design

Provide circuit design services (if the customer does not have a ready-made design)

Selection suggestions (such as chips, sensors, communication modules)

Cost and function trade-off suggestions

Produce schematics and BOM tables

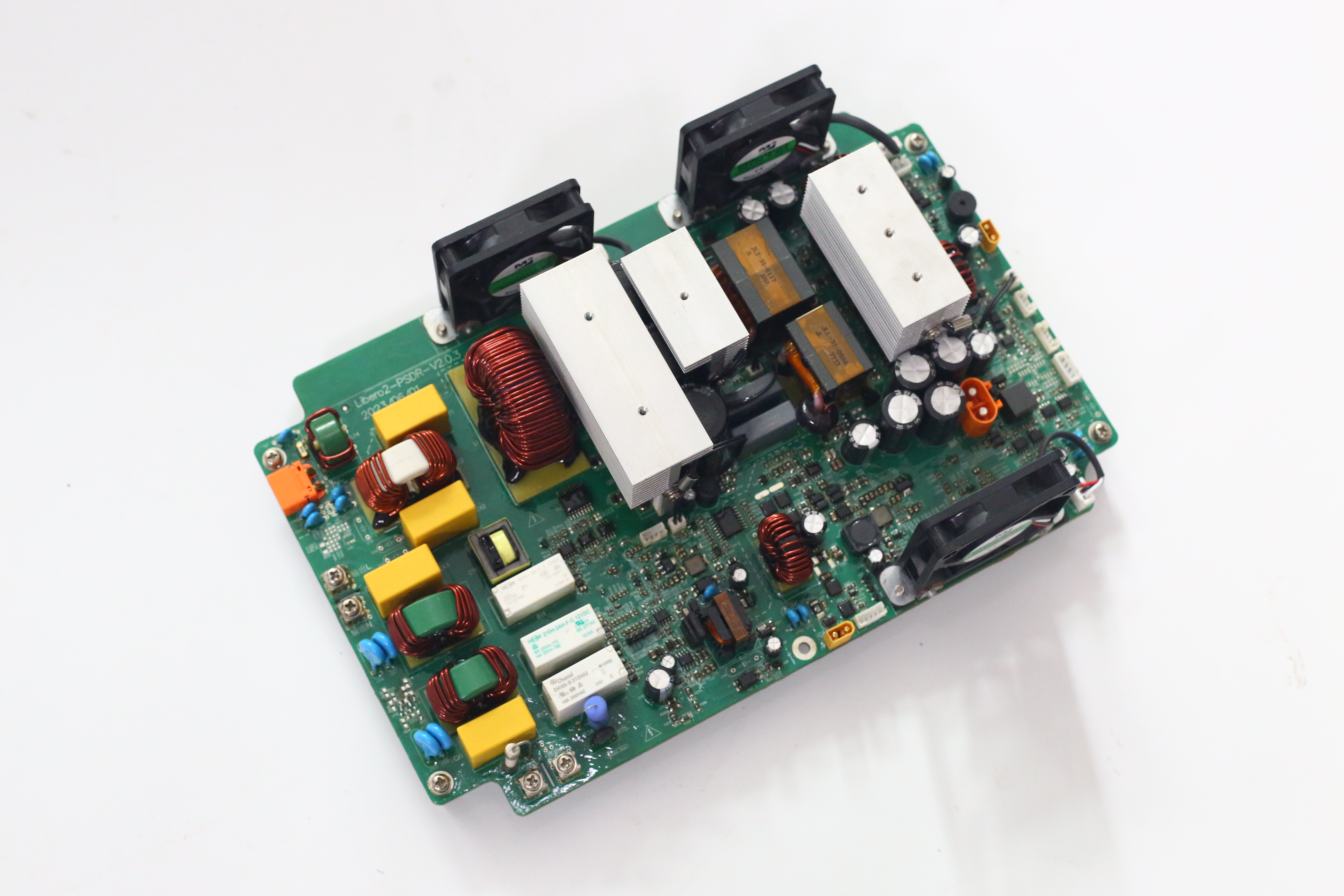

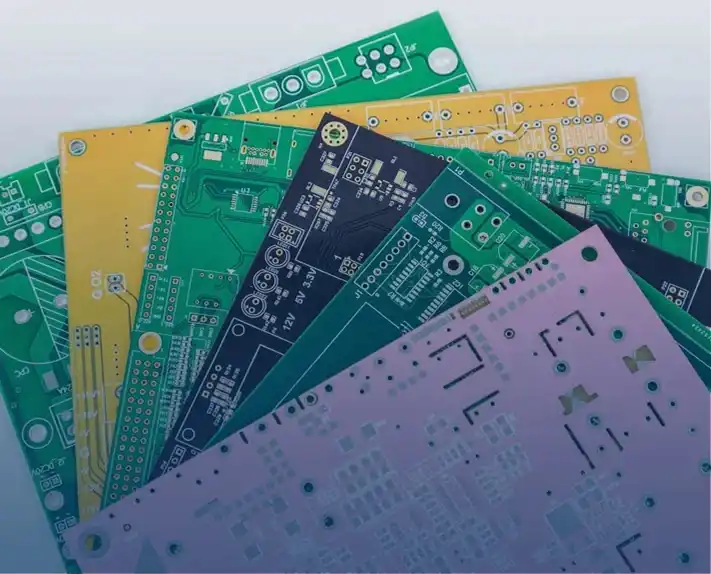

3. PCB design and proofing

Multilayer boards, HDI, flexible boards, etc. are selected according to needs

Output Gerber files and proofing production

Perform pad inspection and electrical rule check (DRC)

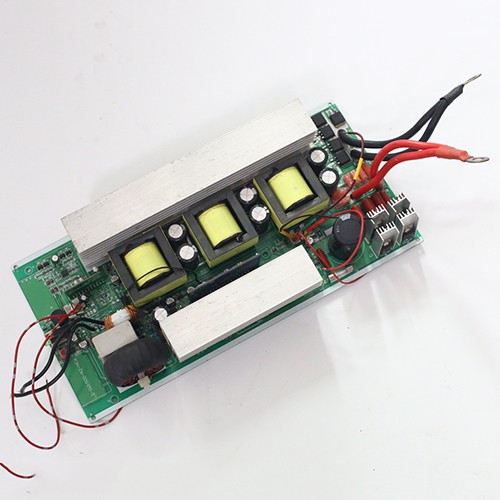

4. SMT patches and DIP plug-ins

High-precision SMT production line, supporting 01005 devices

AOI, SPI, X-ray and other inspections

Can be used with fully automated intelligent production lines (if you are building a smart workshop)

5. Functional test (FCT) and burning

Provide program burning (support ISP/online burning)

Design test fixtures according to customer test points

Complete power-on operation test and data recording

6. Shell assembly/packaging (optional)

If the customer is a complete machine brand, we can cooperate in structural parts assembly

Provide labeling, laser coding, packaging and delivery services