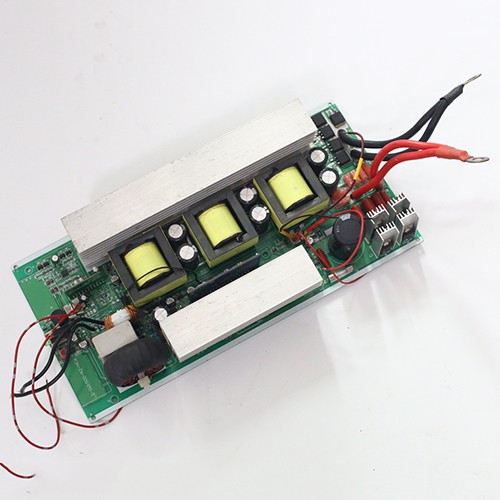

1. Quickly discover obvious defects

Such as component misalignment, offset, flip, missing parts

Solder joints, cold solder joints, solder beads, bridges

PCB surface scratches, pollution, oxidation, etc.

The human eye is very sensitive to color, alignment, offset, and reverse perception. Machine vision is

sometimes prone to misjudgment or omission. Manual inspection is more suitable for discovering these

"visible to the naked eye" anomalies.

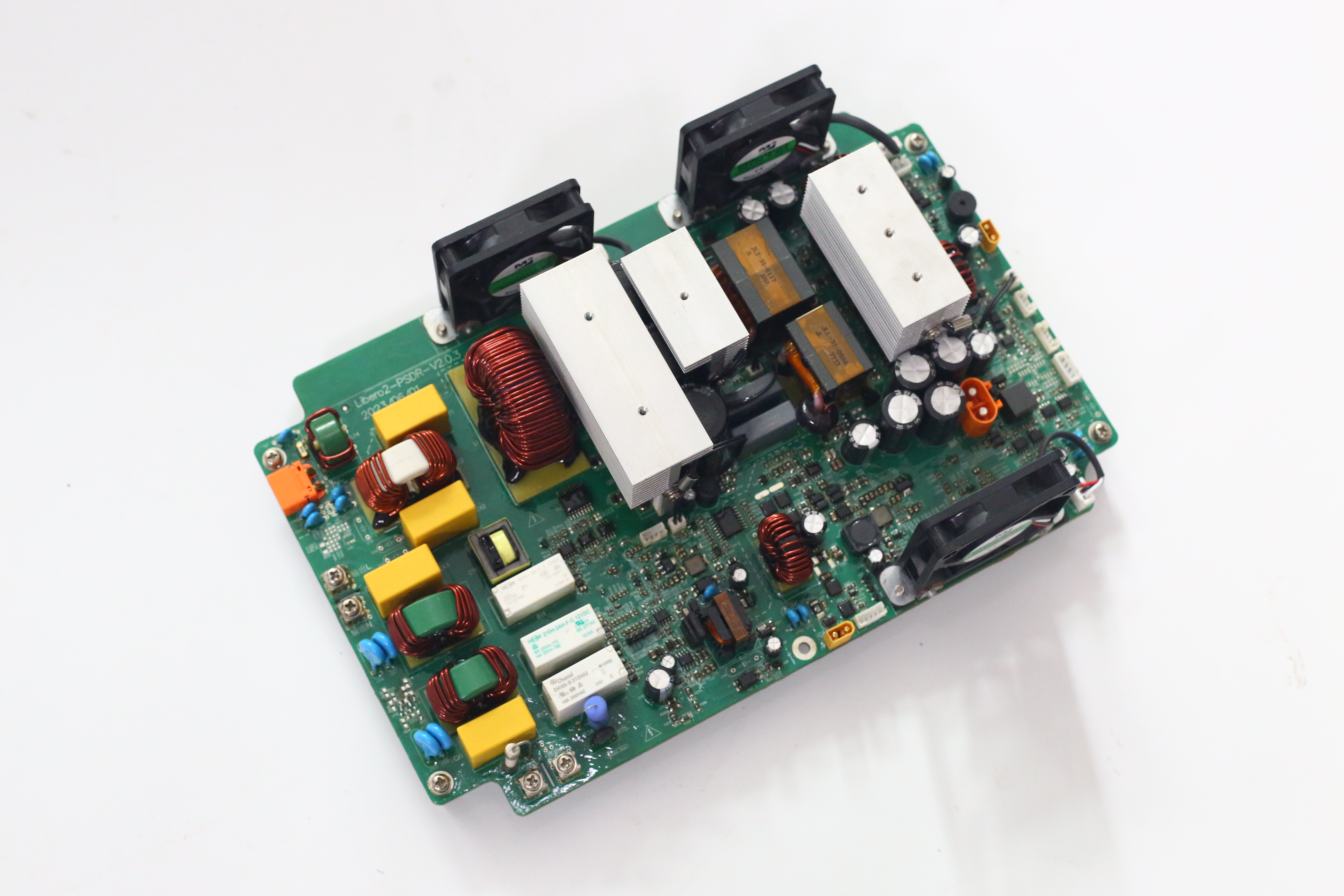

2. As a review mechanism after AOI and SPI

Even if AOI (automatic optical inspection) or SPI (solder paste inspection) is used, manual visual inspection

is still required for review, especially:

Dead corners that AOI cannot detect (such as some large-volume device occlusion areas)

Misjudged or missed items (such as odd-shaped special-shaped parts or special pins)

When the equipment is debugged for the first time, when switching to new products, and when the program

accuracy is not calibrated

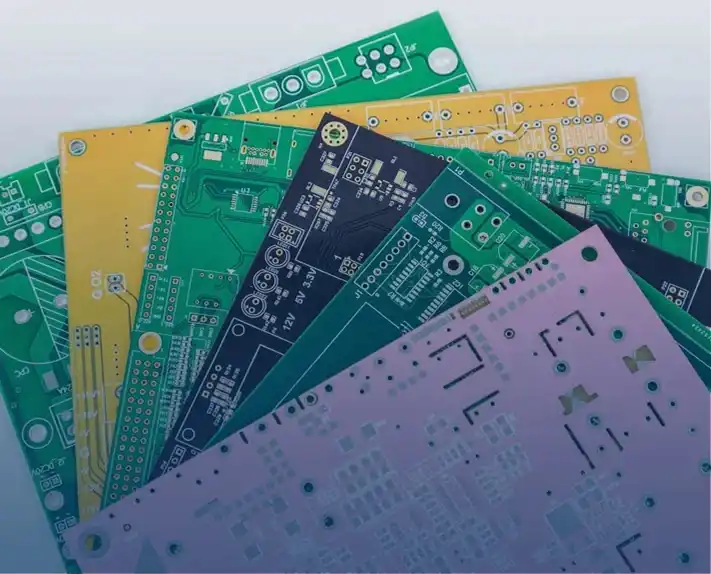

3. Ensure the appearance quality of the product before delivery

Customers also attach great importance to the appearance quality of PCBA, such as solder joint brightness,

uniform solder paste, neat board surface, etc. Many of them need to be guaranteed by visual inspection,

especially in the FQC link before shipment.

4. Training/Newbie/Prototyping stage is extremely critical

During prototyping or trial production:

Visual inspection can help find design errors or process loopholes

Promptly provide feedback to the process and engineering departments for adjustment

It is a bridge for front-line experience accumulation and technical feedback