We have a stable network of component suppliers to ensure the quality and timely supply of raw materials, quickly respond to customer needs and problems, provide timely technical support and after-sales service, provide competitive prices, and at the same time ensure product quality. We support small batch production and rapid prototyping to meet the diverse needs of customers

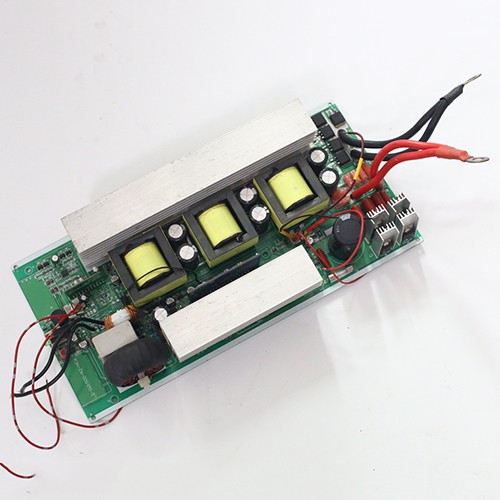

Shenzhen Jintianlei Innovation Technology Co., Ltd. is a global supplier specializing in the research and development, production and sales of new energy, medium and high power inverters, smart city power management systems, smart devices and other products.

The main products are used in automotive charging pile series, high-power energy storage series, smart devices, smart city power management, shared communication digital products, visual vehicle systems, smart bracelets and medical equipment, etc. There are currently more than 150 employees and more than 20 technical and management personnel.

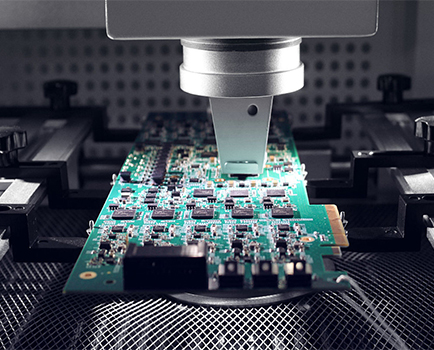

In terms of production: we now have 4 fully automatic Yamaha YS24+YS12 production lines, 3 fully automatic plug-in lines, lead-free wave soldering, welding assembly lines and other production equipment, and currently have a monthly production capacity of 150,000,000 pieces of patch production capacity.

In terms of quality assurance: we now have a number of online testing equipment and instruments, including SMT tin thickness test, adhesion push and pull test, furnace temperature intelligent control system, and PCBA semi-finished product function test, including intelligent Bluetooth signal transmission equipment, electronic oscilloscope, audio and video transmission equipment, etc.

Jintianlei Technology always adheres to the corporate values of "pragmatic, innovative, sincere and win-win", providing customers with high-quality products and services that best fit the market, and is committed to becoming an excellent supplier of core components for global smart electronic products.

The company has cooperated with more than 3,000 high-tech R&D, manufacturing and service companies around the world, and its technical solutions cover medical, industrial control, artificial intelligence, Internet of Things, automotive electronics, smart home and other fields

As the autumn atmosphere deepens, the enthusiasm for learning is at its peak. On the afternoon of November 8th, outstanding entrepreneur representatives from the Bao'an District Xinlianhui 'Ignite Learning' class gathered at the Maolian Group Shenzhen Park to participate in a rich and in-depth corporate visit. From sharing corporate culture to on-site workshop observations, from touring the park to face-to-face exchanges, the entire event was successfully held in a warm and harmonious atmosphere.